What is AQL Meaning?

AQL, full name is Acceptable Quality Limit or Acceptable Quality Level, on the international standard: ISO 2859-1 (ANSI/ASQC Z1.4-2003), it was defined as the maximum percent defective (or the maximum number of defects per hundred units) that, for purpose of sampling inspection, can be considered satisfactory as a process average. According to ISO 9000:2000, “It is the degree to which a set of inherent characteristics fulfills requirements".

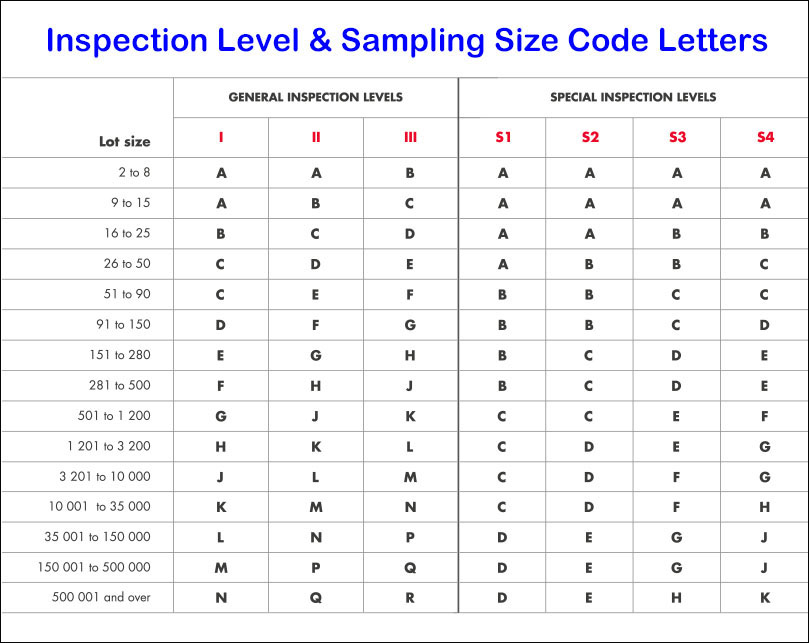

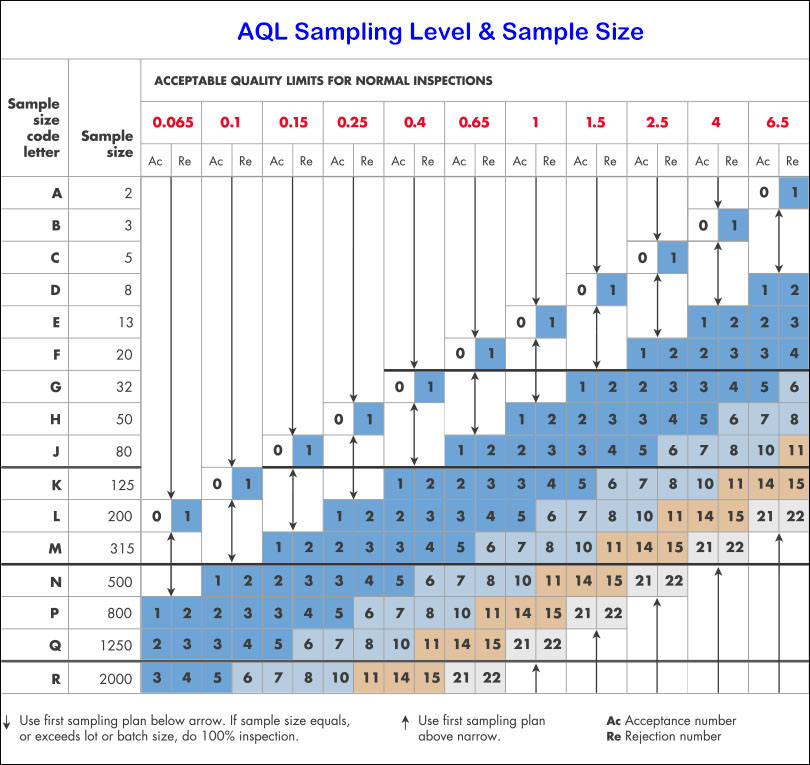

AQL Table

An AQL Table, also named AQL Chart, present a statistics data standard to judge the inspection results. Most pre shipment Inspection are being carried out on the standard. Qualityloyal, as part of China quality inspection services, also carry out the inspection activities on the standard. If necessary, the client is also able to set up another alternative inspection criteria with their supplier on agreement when the contractis established.

AQL Level

AQL Level is defined with different numerical code to decide the standard that would apply on the inspection activities with different aql sampling plan, it ranges 0.065 – 6.5, the lower the stricter, it works with another key criteria Inspection Level to decide the sampling inspected result go or no-go, the Inspection Level is defined by I,II,III for general inspection and S1, S2, S3, S4 for special inspection.

AQL Sampling

AQL sampling is a plan to take random sample from the shipment order when inspecting in supplier site, from result on the inspected sample size’s quality performance, the AQL sampling plan would be different with different shipment quantity range, wouldn't vary with different AQL level selection, it can draw an essential conclusion on what quality level of the product quality, helps client T make decision on accepting, reject or other necessary corrective action to be taken by supplier to fix the defective issues that were detected during inspection, the report would present the final result on the sampling plan, instead of full order, and kept by the client, therefore, the client could make decision on accept or reject with the result coming out. Basing on this, the AQL Table (AQL Chart) also named AQL Sampling Table (AQL Sampling Chart).

How to Determine the AQL Level and Defect Type for Your Inspection?

You would like to know what inspection level is suitable for your quality inspection and determine if the result is proper and acceptable.

A defect is imperfection of a product which contains one or more faults. Failure to meet requirements with respect to quality characteristics are usually described in terms of defects or defectives. There are mainly 3 types of defects:

• Critical defects

• Major defects

• Minor defects

While these can vary from client to client, the typical definitions are as follow:

• A Minor defect is a discrepancy from the standards, but one that is not likely to affect the usability of an object.

• A Major defect is one that is likely to create failure of the unit for its intended purpose.

• A Critical defect is one that is deemed to be hazardous or unsafe.

Accepting or rejecting of a lot depends on the number of defectives found by sampling according to AQL chart. The previous chart for AQL were given for better understanding.

Generally, applying AQL level to defect type, we select as following methodology:

- For Critical defects, AQL 0.065

- For Major defects, AQL 2.5;

-

For Minor defects, AQL 4.0.

The client also request different level for his/her product inspection, but it should make agreement with supplier before the inspection is on, because it could make argue on the result judgement for different from standard.

Leave a comment

Please note, comments must be approved before they are published